April, 02 2018, 12:45pm EDT

For Immediate Release

Contact:

Darcey Rakestraw, 202-683-2467; drakestraw@fwwatch.org, Peter Hart, 732-839-0871; phart@fwwatch.org

Five Questions USDA Secretary Perdue Should Ask Before Lunch at the Clemens Hog Slaughter Plant in Coldwater, Michigan

Secretary to visit hog slaughter facility piloting controversial privatized inspection model; documents obtained by Food & Water Watch raise serious questions about facility.

WASHINGTON

On the eve of a visit from USDA Secretary Sonny Perdue on April 3, new documents obtained by Food & Water Watch raise serious questions about safety at a new "state of the art" hog slaughter plant in Michigan that is seeking to partially privatize its inspections process.

The Clemens Foods hog slaughter plant began operations in September 2017, with a full complement of USDA inspectors working the slaughter line. The plant has since been granted regulatory waivers to partially privatize its inspections and increase its slaughter line speed, and Food & Water Watch is urging Secretary Perdue to question plant managers on several aspects of the new privatization scheme uncovered in the documents.

"We wanted to help the Secretary out with some background on the track record of this facility's controversial hog inspection pilot program," said Tony Corbo, Senior Lobbyist at Food & Water Watch. "Company records raise important questions Perdue should ask company officials during his visit."

Prior to the opening of the new Clemens plant, pork industry trade publications were projecting that the plant would be slaughtering 12,000 head per day on one slaughter line, or 1,500 head per hour. The current line speed cap in a high-speed hog slaughter plant that receives traditional inspection is set at just 1,106 head per hour, with seven USDA inspectors stationed at key points of the slaughter process.

But the Clemens' Michigan plant was granted a regulatory waiver by the agency on September 22, 2017 to reduce the number of USDA slaughter line inspectors from 5 to 2. The USDA also permitted the plant to run its slaughter line as fast as it could, provided that it could "maintain process control." The vacated positions of USDA inspectors would be assumed by plant employees, who would also conduct ante-mortem inspections of live animals before they entered the slaughter line. It seems that the plant was being used by USDA's Food Safety and Inspection Service (FSIS) as a demonstration project to support expansion of this privatized inspection model. On February 1, 2018, FSIS proposed a rule - called the New Swine Slaughter Inspection System - to expand this privatized inspection model to all hog slaughter facilities.

Food & Water Watch filed two separate Freedom of Information Act requests for documents regarding this "state-of-the-art" plant. The documents revealed several issues that Secretary Perdue should ask company officials about during his visit:

- The plant implemented its regulatory waiver program on December 7, 2017. In a December 19, 2017 email from FSIS District Manager Paul Wolseley to FSIS headquarters staff (p. 1), he reported that as the plant increased its line speed, it reached a point where it "lost process control" and was forced to reduce the slaughter line speed. The line speed at which the plant "lost process control" was redacted, and the reason it "lost process control" was never identified.

The first question Secretary Perdue should ask the Clemens company officials is: What was the line speed at which the plant "lost process control" and what was the reason the plant was forced to reduce its line speed? Furthermore, at what line speed is the slaughter line currently running?

- On December 12, 2017, just five days after the plant shifted to the privatized inspection model, a non-compliance report was filed (pp. 2-3) against the plant because a plant employee who had been charged with conducting ante-mortem inspection of animals prior to slaughter failed to notice a dead hog in the holding pen. One of the concerns with turning over inspection duties to plant personnel is that there is no guarantee that they will be properly trained to perform those tasks that had been formerly performed by FSIS inspectors and veterinarians. Some in the veterinary community have expressed concern that untrained plant employees will not be able to detect exotic animal diseases, such as foot-and-mouth disease, that could devastate the entire livestock industry should they go unnoticed - or be properly trained to identify downed animals.

The second question the Secretary - a veterinarian by profession - should ask the Clemens company officials: How are your employees trained to detect animal diseases and to identify downed or dead hogs prior to slaughter during the ante-mortem inspection process? How often do they receive this training and do you test them for proficiency? What kind of training do your employees receive for post-mortem inspection? How often do they receive training and do they get tested for proficiency?

- Even though this plant is being advertised as "state-of-the-art," there was a design flaw discovered by FSIS inspection personnel (p. 23). It seems that hog carcasses swing so wildly on one part of the line that they inadvertently hit the stop button for the entire slaughter line.

The third question the Secretary should ask the Clemens company officials: Has the issue with the hog carcasses inadvertently striking the stop button on the slaughter line been resolved?

- Even though this is a new plant, it has already been cited numerous times (pp. 4-22) by FSIS inspectors for improper sanitation during pre-operational inspection checks.

The fourth question the Secretary should ask the Clemens company officials: What are you doing to ensure that proper sanitation of the plant is conducted prior to the start of operations each day?

- On the processing side of the plant, FSIS inspectors reported (p. 23) that meat often falls off of conveyer belts.

The fifth question the Secretary should ask the Clemens company officials: Have you been able to address the issue of meat falling off conveyor belts on the processing side of your plant to FSIS' satisfaction?

"These are all legitimate questions that need to be asked and addressed prior to using the Clemens plant experiment as a justification for the implementation to new inspection system across the entire pork industry that seems to yield no improvements in food safety," said Corbo. "We hope the Secretary asks these questions on his visit and will make the information available to the general public."

View the documents obtained by Food & Water Watch at: https://www.foodandwaterwatch.org/sites/default/files/clemens_foia_documents.pdf

Food & Water Watch mobilizes regular people to build political power to move bold and uncompromised solutions to the most pressing food, water, and climate problems of our time. We work to protect people's health, communities, and democracy from the growing destructive power of the most powerful economic interests.

(202) 683-2500LATEST NEWS

‘Don't Give the Pentagon $1 Trillion,’ Critics Say as House Passes Record US Military Spending Bill

"From ending the nursing shortage to insuring uninsured children, preventing evictions, and replacing lead pipes, every dollar the Pentagon wastes is a dollar that isn't helping Americans get by," said one group.

Dec 10, 2025

US House lawmakers on Wednesday approved a $900.6 billion military spending bill, prompting critics to highlight ways in which taxpayer funds could be better spent on programs of social uplift instead of perpetual wars.

The lower chamber voted 312-112 in favor of the National Defense Authorization Act (NDAA) for fiscal year 2026, which will fund what President Donald Trump and congressional Republicans call a "peace through strength" national security policy. The proposal now heads for a vote in the Senate, where it is also expected to pass.

Combined with $156 billion in supplemental funding included in the One Big Beautiful Bill signed in July by Trump, the NDAA would push military spending this fiscal year to over $1 trillion—a new record in absolute terms and a relative level unseen since World War II.

The House is about to vote on authorizing $901 billion in military spending, on top of the $156 billion included in the Big Beautiful Bill.70% of global military spending already comes from the US and its major allies.www.stephensemler.com/p/congress-s...

[image or embed]

— Stephen Semler (@stephensemler.bsky.social) December 10, 2025 at 1:16 PM

The Congressional Progressive Caucus (CPC) led opposition to the bill on Capitol Hill, focusing on what lawmakers called misplaced national priorities, as well as Trump's abuse of emergency powers to deploy National Guard troops in Democratic-controlled cities under pretext of fighting crime and unauthorized immigration.

Others sounded the alarm over the Trump administration's apparent march toward a war on Venezuela—which has never attacked the US or any other country in its nearly 200-year history but is rich in oil and is ruled by socialists offering an alternative to American-style capitalism.

"I will always support giving service members what they need to stay safe but that does not mean rubber-stamping bloated budgets or enabling unchecked executive war powers," CPC Deputy Chair Ilhan Omar (D-Minn.) said on social media, explaining her vote against legislation that "pours billions into weapons systems the Pentagon itself has said it does not need."

"It increases funding for defense contractors who profit from global instability and it advances a vision of national security rooted in militarization instead of diplomacy, human rights, or community well-being," Omar continued.

"At a time when families in Minnesota’s 5th District are struggling with rising costs, when our schools and social services remain underfunded, and when the Pentagon continues to evade a clean audit year after year, Congress should be investing in people," she added.

The Congressional Equality Caucus decried the NDAA's inclusion of a provision banning transgender women from full participation in sports programs at US military academies:

The NDAA should invest in our military, not target minority communities for exclusion.While we're grateful that most anti-LGBTQI+ provisions were removed, the GOP kept one anti-trans provision in the final bill—and that's one too many.We're committed to repealing it.

[image or embed]

— Congressional Equality Caucus (@equality.house.gov) December 10, 2025 at 3:03 PM

Advocacy groups also denounced the legislation, with the Institute for Policy Studies' National Priorities Project (NPP) noting that "from ending the nursing shortage to insuring uninsured children, preventing evictions, and replacing lead pipes, every dollar the Pentagon wastes is a dollar that isn't helping Americans get by."

"The last thing Congress should do is deliver $1 trillion into the hands of [Defense] Secretary Pete Hegseth," NPP program director Lindsay Koshgarian said in a statement Wednesday. "Under Secretary Hegseth's leadership, the Pentagon has killed unidentified boaters in the Caribbean, sent the National Guard to occupy peaceful US cities, and driven a destructive and divisive anti-diversity agenda in the military."

Keep ReadingShow Less

Fed Cut Interest Rates But Can't Undo 'Damage Created by Trump's Chaos Economy,' Expert Says

"Working families are heading into the holidays feeling stretched, stressed, and far from jolly."

Dec 10, 2025

A leading economist and key congressional Democrat on Wednesday pointed to the Federal Reserve's benchmark interest rate cut as just the latest evidence of the havoc that President Donald Trump is wreaking on the economy.

The US central bank has a dual mandate to promote price stability and maximum employment. The Federal Open Market Committee may raise the benchmark rate to reduce inflation, or cut it to spur economic growth, including hiring. However, the FOMC is currently contending with a cooling job market and soaring costs.

After the FOMC's two-day monthly meeting, the divided committee announced a quarter-point reduction to 3.5-3.75%. It's the third time the panel has cut the federal funds rate in recent months after a pause during the early part of Trump's second term.

"Today's decision shows that the Trump economy is in a sorry state and that the Federal Reserve is concerned about a weakening job market," House Budget Committee Ranking Member Brendan Boyle (D-Pa.) said in a statement. "On top of a flailing job market, the president's tariffs—his national sales tax—continue to fuel inflation."

"To make matters worse, extreme Republican policies, including Trump's Big Ugly Law, are driving healthcare costs sharply higher," he continued, pointing to the budget package that the president signed in July. "I will keep fighting to lower costs and for an economy that works for every American."

Alex Jacquez, a former Obama administration official who is now chief of policy and advocacy at the Groundwork Collaborative, similarly said that "Trump's reckless handling of the economy has backed the Fed into a corner—stuck between rising costs and a weakening job market, it has no choice but to try and offer what little relief they can to consumers via rate cuts."

"But the Fed cannot undo the damage created by Trump's chaos economy," Jacquez added, "and working families are heading into the holidays feeling stretched, stressed, and far from jolly."

Thanks to the historically long federal government shutdown, the FOMC didn't have typical data—the consumer price index or jobs report—to inform Wednesday's decision. Instead, its new statement and projections "relied on 'available indicators,' which Fed officials have said include their own internal surveys, community contacts, and private data," Reuters reported.

"The most recent official data on unemployment and inflation is for September, and showed the unemployment rate rising to 4.4% from 4.3%, while the Fed's preferred measure of inflation also increased slightly to 2.8% from 2.7%," the news agency noted. "The Fed has a 2% inflation target, but the pace of price increases has risen steadily from 2.3% in April, a fact at least partly attributable to the pass-through of rising import taxes to consumers and a driving force behind the central bank's policy divide."

The lack of government data has also shifted journalists' attention to other sources, including the revelation from global payroll processing firm ADP that the US lost 32,000 jobs in November, as well as Gallup's finding last week that Americans' confidence in the economy has fallen by seven points over the past month and is now at its lowest level in over a year.

The Associated Press highlighted that the rate cut is "good news" for US job-seekers:

"Overall, we've seen a slowing demand for workers with employers not hiring the way they did a couple of years ago," said Cory Stahle, senior economist at the Indeed Hiring Lab. "By lowering the interest rate, you make it a little more financially reasonable for employers to hire additional people. Especially in some areas—like startups, where companies lean pretty heavily on borrowed money—that's the hope here."

Stahle acknowledged that it could take time for the rate cuts to filter down to employers and then to workers, but he said the signal of the reduction is also important.

"Beyond the size of the cut, it tells employers and job-seekers something about the Federal Reserve's priorities and focus. That they're concerned about the labor market and willing to step in and support the labor market. It's an assurance of the reserve's priorities."

The Federal Reserve is now projecting only one rate cut next year. During a Wednesday press conference, Fed Chair Jerome Powell pointed to the three cuts since September and said that "we are well positioned to wait to see how the economy evolves."

However, Powell is on his way out, with his term ending in May, and Trump signaled in a Tuesday interview with Politico that agreeing with immediate interest rate cuts is a litmus test for his next nominee to fill the role.

Trump—who embarked on a nationwide "affordability tour" this week after claiming last week that "the word 'affordability' is a Democrat scam"—also graded the US economy on his watch, giving it an A+++++.

US Sen. Bernie Sanders (I-Vt.) responded: "Really? 60% of Americans live paycheck to paycheck. 800,000 are homeless. Food prices are at record highs. Wages lag behind inflation. God help us when we have a B+++++ economy."

Keep ReadingShow Less

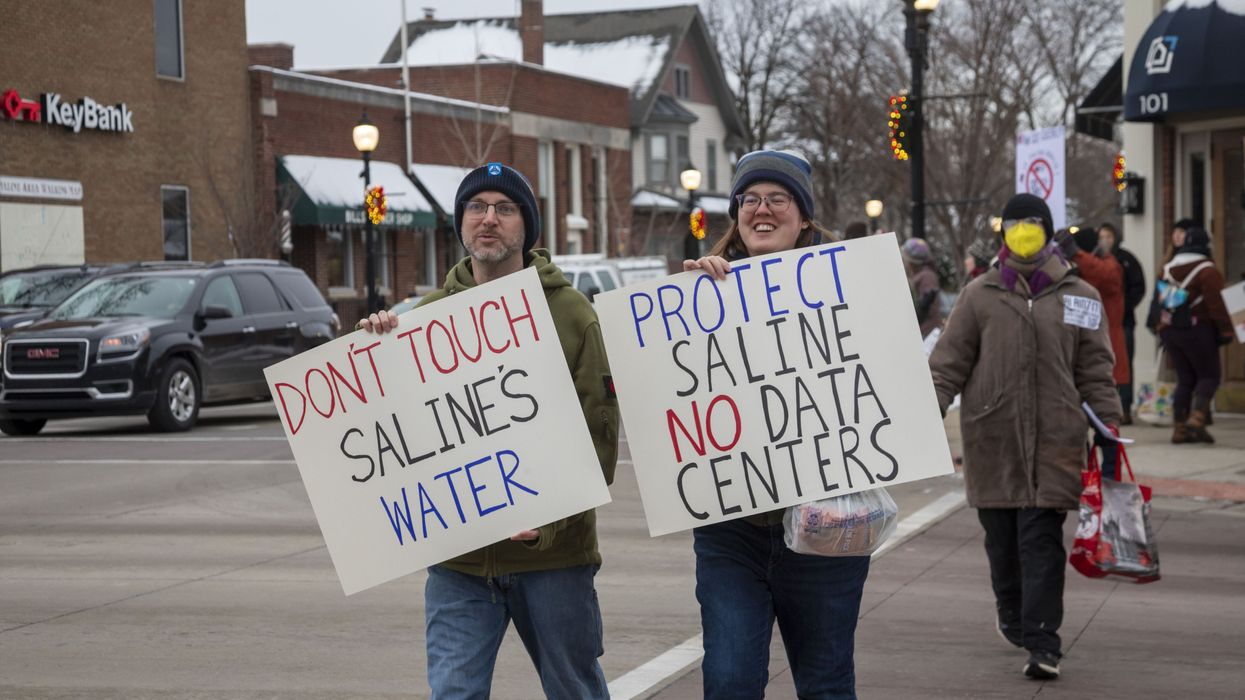

Sanders Champions Those Fighting Back Against Water-Sucking, Energy-Draining, Cost-Boosting Data Centers

Dec 10, 2025

Americans who are resisting the expansion of artificial intelligence data centers in their communities are up against local law enforcement and the Trump administration, which is seeking to compel cities and towns to host the massive facilities without residents' input.

On Wednesday, US Sen. Bernie Sanders (I-Vt.) urged AI data center opponents to keep up the pressure on local, state, and federal leaders, warning that the rapid expansion of the multi-billion-dollar behemoths in places like northern Virginia, Wisconsin, and Michigan is set to benefit "oligarchs," while working people pay "with higher water and electric bills."

"Americans must fight back against billionaires who put profits over people," said the senator.

In a video posted on the social media platform X, Sanders pointed to two major AI projects—a $165 billion data center being built in Abilene, Texas by OpenAI and Oracle and one being constructed in Louisiana by Meta.

The centers are projected to use as much electricity as 750,000 homes and 1.2 million homes, respectively, and Meta's project will be "the size of Manhattan."

Hundreds gathered in Abilene in October for a "No Kings" protest where one local Democratic political candidate spoke out against "billion-dollar corporations like Oracle" and others "moving into our rural communities."

"They’re exploiting them for all of their resources, and they are creating a surveillance state,” said Riley Rodriguez, a candidate for Texas state Senate District 28.

In Holly Ridge, Lousiana, the construction of the world's largest data center has brought thousands of dump trucks and 18-wheelers driving through town on a daily basis, causing crashes to rise 600% and forcing a local school to shut down its playground due to safety concerns.

And people in communities across the US know the construction of massive data centers are only the beginning of their troubles, as electricity bills have surged this year in areas like northern Virginia, Illinois, and Ohio, which have a high concentration of the facilities.

The centers are also projected to use the same amount of water as 18.5 million homes normally, according to a letter signed by more than 200 environmental justice groups this week.

And in a survey of Pennsylvanians last week, Emerson College found 55% of respondents believed the expansion of AI will decrease the number of jobs available in their current industry. Sanders released an analysis in October showing that corporations including Amazon, Walmart, and UnitedHealth Group are already openly planning to slash jobs by shifting operations to AI.

In his video on Wednesday, Sanders applauded residents who have spoken out against the encroachment of Big Tech firms in their towns and cities.

"In community after community, Americans are fighting back against the data centers being built by some of the largest and most powerful corporations in the world," said Sanders. "They are opposing the destruction of their local environment, soaring electric bills, and the diversion of scarce water supplies."

Keep ReadingShow Less

Most Popular